Wrapping your own silage might mean a few days of sitting in a climate-controlled cabin, while listening to the radio. But are you better off getting a contractor to do it? The first step to answering this question is understanding how much it’s costing you to own and run a silage wrapper. Farm machinery costs are easily underestimated because of the infrequent cash outlays and large non-cash costs. However, with the help of some rules of thumb, the good news is all you need is the calculator on your phone to estimate how much it’s costing you.

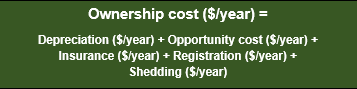

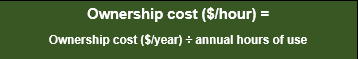

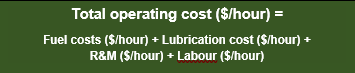

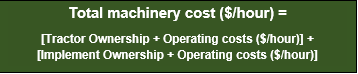

Farm machinery costs can be divided into two categories: Ownership costs and Operating costs. The true value of these costs cannot be known until the machine is sold or worn out. But the costs can be estimated by making a few assumptions about machine life, value and annual use.

Ownership Costs

Ownership costs (or overhead costs) are incurred whether the machine or implement is used or not. Items included in this category are:

- Depreciation: A non-cash cost that reflects the annual loss in value of machinery (Rule of thumb: $/year = [purchase cost – trade in value] ÷ years owned)

- Opportunity cost: The capital invested in the machine has an opportunity cost as the money could earn interest in another use (Rule of thumb: $/year = average value of machine (purchase cost – trade-in value ÷ 2) x alternative investment earning rate)

- Insurance: Annual cost to provide cover for damage to the machine or implement (Rule of thumb: $/year = 1% x average value of the machine)

- Registration: Annual costs for registering the equipment to drive on the road

- Shedding: Depreciation cost of owning the shed and the proportion of the shed devoted to that machine. (Rule of thumb: $/year= 0.5% x average value of the equipment)

Operating Costs

Operating costs (or variable costs) vary with the number of hours of operation of machine or implement use. Costs for implements or attachments that depend on tractor power are estimated in the same way as described below, except that there are no fuel, lubrication, or labour costs.

- Fuel costs: The cost of fuel use varies proportionally with the power of the engine and are minor for non-powered equipment. (Rule of thumb: Fuel cost/hour = [ Horsepower x 0.16] x fuel price $/L)

- Lubrication cost: Costs for lubricants and filters for tractors (Rule of thumb: Lubrication costs/hour = 10% of fuel costs)

- Repairs and maintenance: Repair costs occur because of routine maintenance, wear and tear, and accidents. (Rule of thumb: 4WD Tractor: R&M cost/hour = New price x 0.005 ÷ 100

Rule of thumb: Round wrapper: R&M cost/hour = New price x 0.06 ÷ 100) - Labour: Labour rate ($/hour) multiplied by the number of hours of operation. (Rule of thumb: the hourly cost for unpaid farm labour is the expected hourly cost to replace them (eg. if the owner manager is operating the machine, the hourly rate would be the cost of getting someone in to manage the farm)

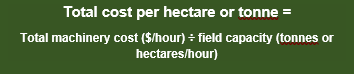

- Field capacity (work rate): The rate at which the machine and implement perform their primary function. Field capacity is most commonly expressed as tonnes (or bales) produced per hour or hectares covered per hour.

Worked example: Wrapping 1,000 bales of silage per year.

Below is a worked example with some typical values and specifications. The size, value and speed of wrapping will vary for each farm business. The cost of wrapping plastic is not included in this example and is an additional cost that should be factored when making a decision. Below the worked example is a blank cost framework so you can input numbers relevant to your machinery to make the cost specific to your farm business.

Example of Tractor Ownership Costs

| Average hours of use per year | 500 | |||||||

| Purchase value | Trade in value | number of years owned | Depreciation ($/year) | |||||

| $100,000 | minus | $37,000 | divided | 10 | equals | $6,300 | ||

| Purchase value | Trade in value | Average value | Return rate of another investment | Opportunity cost ($/year) | ||||

| $100,000 | minus | $37,000 | divided by 2 | $31,500 | multiplied | 5% | equals | $1,575 |

| Average value | Insurance cost ($/year) | |||||||

| $31,500 | multiplied | 0.01 | equals | $315 | ||||

| Average value | Shedding cost ($/year) | |||||||

| $31,500 | multiplied | 0.005 | equals | $158 | ||||

| Registration cost ($/year) | ||||||||

| $200 | ||||||||

Example of Silage Wrapper Ownership Costs

| Number of bales wrapped (bales/year) | 1000 | ||||||||

| divide | |||||||||

| Work rate of wrapper (bales/hour) | 60 | ||||||||

| equals | |||||||||

| Average annual hours of use per year | 17 | ||||||||

| Purchase value | Trade in value | number of years owned | Depreciation ($/year) | ||||||

| $50,000 | minus | $14,000 | divided | 10 | equals | $3,600 | |||

| Purchase value | Trade in value | Average value | Return rate of another investment | Opportunity cost ($/year) | |||||

| $50,000 | minus | $14,000 | divided by 2 | $18,000 | multiplied | 5% | equals | $900 | |

| Average value | Insurance cost ($/year) | ||||||||

| $18,000 | multiplied | 0.01 | equals | $180 | |||||

| Average value | Shedding cost ($/year) | ||||||||

| $18,000 | multiplied | 0.005 | equals | $90 | |||||

| Registration cost ($/year) | |||||||||

| $100 | |||||||||

Example of Tractor Operating Costs

| Horsepower | Fuel price | Fuel cost ($/hr) | ||||

| 100 | multiplied | 0.16 | multiplied | $1.40 | equals | $22 |

| Fuel cost ($/hr) | Lubrication cost ($/hr) | |||||

| $22 | multiplied | 0.1 | equals | $2 | ||

| Purchase value | Repairs and maintenance cost ($/hr) | |||||

| $100,000 | multiplied | 0.005 | divided by 100 | $5 | ||

| Labour cost ($/hour) | ||||||

| $30 |

Example of Silage Wrapper Operating Costs

| Purchase value | Repairs and maintenance cost ($/hr) | |||

| $50,000 | multiplied | 0.06 | divided by 100 | $30 |

Summary of the cost to wrap your own silage (exclusive of plastic)

| Ownership | Tractor | Wrapper | |

| Depreciation ($/year) | $6,300 | $3,600 | |

| Opportunity cost ($/year) | $1,575 | $900 | |

| Insurance cost ($/year) | $315 | $180 | |

| Shedding cost ($/year) | $158 | $90 | |

| Registration cost ($/year) | $200 | $100 | Total |

| Total ownership cost ($/year) | $8,548 | $4,870 | $13,418 |

| Total ownership cost ($/hour) | $17 | $292 | $309 |

| Operating | Tractor | Wrapper | |

| Fuel cost ($/hour) | $22 | ||

| Lubrication cost ($/hour) | $2 | ||

| Repairs and maintenance cost ($/hour) | $5 | $30 | |

| Labour cost ($/hour) | $30 | Total | |

| Total operating costs ($/hour) | $60 | $30 | $90 |

| Total ownership and operating costs ($/hour) | $77 | $322 | $399 |

| divide | |||

| Work rate of wrapper (bales/hour) | 60 | ||

| equals | |||

| Total cost ($/bale) | $7 | ||

Further Information

For further information please contact: Sam Henty, Farm Business Economist, Agriculture Victoria

Further Reading and References

Malcolm B, Makeham J, Wright V (2005) ‘The Farming Game – Agricultural Management and Marketing.’ Cambridge University Press

Kay RD, Edwards WM, Duffy PA (2004) ‘Farm Management’ Mcgraw-Hill Companies

Hanna M (2016) Estimating the field capacity of farm machines. Ag Decision Maker. Iowa State University. https://www.extension.iastate.edu/agdm/crops/html/a3-29.html

Davies L, Khairo K (2009) Guide to machinery costs and contract rates. NSW Department of Primary Industries. https://www.dpi.nsw.gov.au/agriculture/budgets/machinery-water

Click here to download a blank Machinery Costs Framework in PDF format.