Energy Efficiency Upgrades

Following an on-farm energy assessment, a number of recommendations were adopted to improve the energy efficiency of milk harvesting processes in the dairy.

This included installing a compact chiller to improve the milk cooling process. In addition, a chiller equipped with a heat recovery system was recommended and selected as it contributes to the water heating process too. Hot water is required for cleaning.

The new compact chiller was sized to match the farm’s milk production so that rapid cooling of milk can be achieved, contributing to high quality standards.

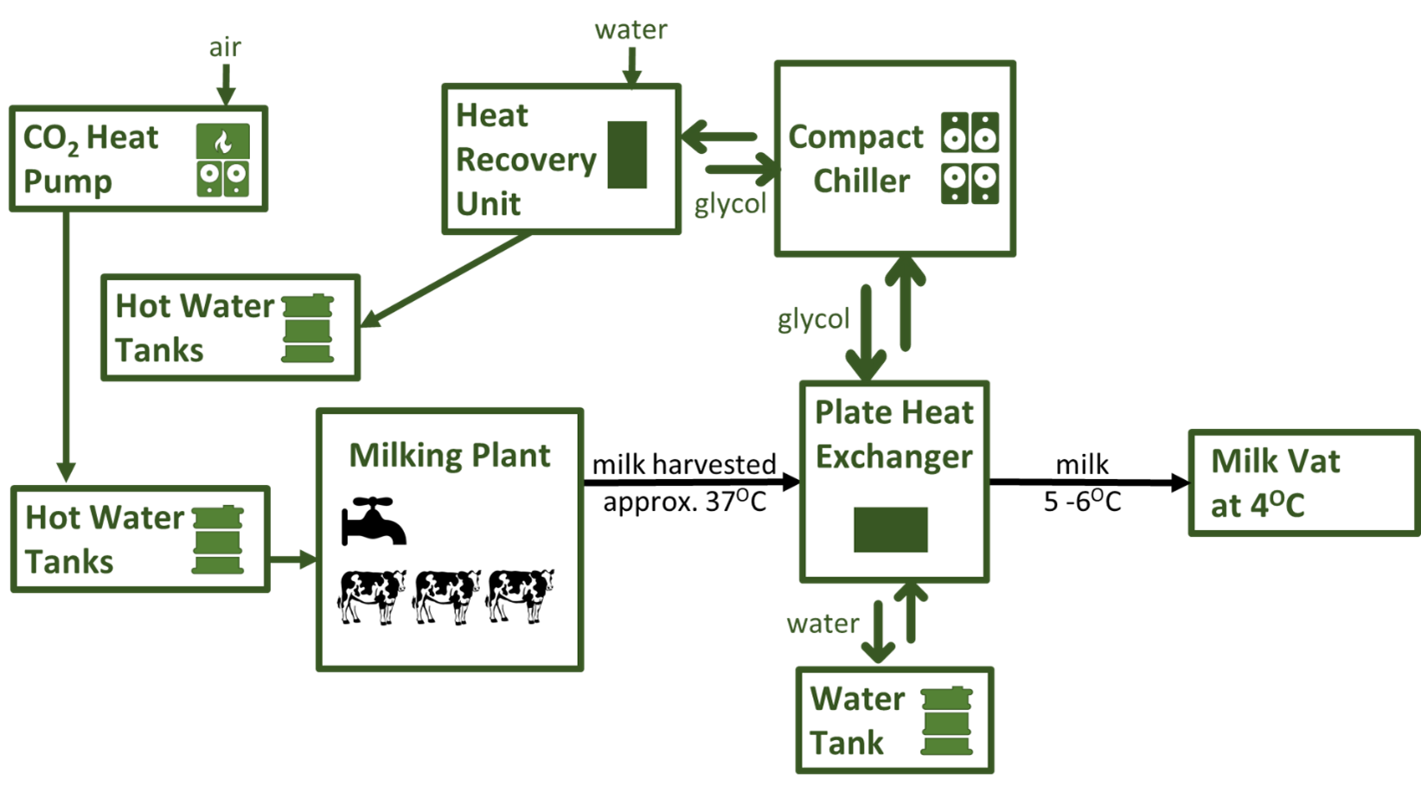

Milk Cooling Chiller System

Milk collected during milking comes out of the cows at around 37°C. It is pre-cooled through a plate heat exchanger before entering a vat where it is cooled further and stored at 4 °C.

A compact chiller helps to cool the milk down further prior to entering the vat. Cold glycol running between the chiller and plate helps to lower the temperature of the milk more rapidly than using cold water alone.

Before the installation of the new compact chiller, the milk from the Ellinbank herd was exiting the plate cooler and entering the vat at around 15°C. Since the installation of the chiller, the milk now exits the plate cooler and enters the vat at 5-6°C.

The extra cooling provided by the new chiller means that the vat compressor does not have to work as hard to reduce milk temperature to the required 4°C.

The chiller’s pre-cooling process is more energy efficient than the vat, so this saves overall energy use in the dairy.

Heat Recovery System (HRS)

The new compact chiller model is equipped with a heat recovery system (HRS). During the cooling process, heat exchange occurs in the chiller. Heat recovered from the warm milk is used to pre-heat the water supply to the hot water system, reducing energy costs.

The hot water is flushed through the dairy plant for cleaning after each milking. This HRS can produce 0.7 litres of warm water (approx. 53°C) from every litre of warm milk (approx. 35°C).

Ellinbank Configuration

Key Components

- Plate Heat Exchanger: milk (at about 37°C) collected from cows is pre-cooled through the plate heat exchanger. It decreases the milk temperature before entering the milk vat.

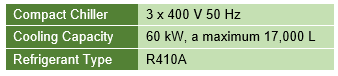

- Compact Chiller: is used for cooling of milk and can be installed into traditional or automatic milking systems. Our model is designed for water and glycol solution.

- Heat Recovery Unit: is equipped with tubular heat exchanger for water and/or glycol solution.

Ellinbank Smart Farm Dairy Energy Upgrades

Further Information

The Ellinbank SmartFarm in Gippsland is Australia’s leading dairy innovation facility, fast-tracking innovative technology solutions in a research environment and showcasing them to the dairy industry. With a target of becoming a carbon-neutral dairy farm, energy efficient technologies are being used for milk harvesting to help achieve this goal.

See the Ellinkbank Dashboard for more details.

Download: Ellinbank – Fact Sheet – Dairy Chiller (PDF -2.0MB)