Improving water use efficiency and maintaining best practice management is a priority for most irrigators.

Hort Innovation, using the almond research and development levy and contributions from the Australian Government, funded a project to determine best practice management for Almond irrigation and equip growers with tools to improve water use efficiency.

Watch this video: https://vimeo.com/395636454/87b5b60c40

The project, conducted by the South Australian Research and Development Institute (SARDI), with assistance from Agriculture Victoria and Netafim Australia, involved a drip irrigation system performance audit of the Australian almond industry across the major almond growing regions of South Eastern Australia (Adelaide Plains, Riverland, Sunraysia, and Riverina).

Watch this video: https://vimeo.com/403547878/f41d8bf468

Audits of 50 irrigation valve units were assessed against a set of standard performance indicators which included:

- Pressure variation (<±10% from midpoint between highest and lowest pressures),

- Flow variation (<±5% from midpoint between highest and lowest flows),

- Flow variation from design (<±5% from design),

- Coefficient of Uniformity (>90%), and

- Test lateral flow rate (<±5% variation from quoted flow rate).

The performance of value units was also compared to other factors including the age of the system, flushing frequency, chemical dosing frequency, water source and filter type.

Key Findings from the audit include:

- Variation in dripper outlet flow rate across individual valve units was greater than recommended in over 80% of sites evaluated

- Age of dripline was a key contributor to drip system performance

- Frequency of dripline flushing correlated well with drip system performance, and indicated that flushing is generally not carried out often enough

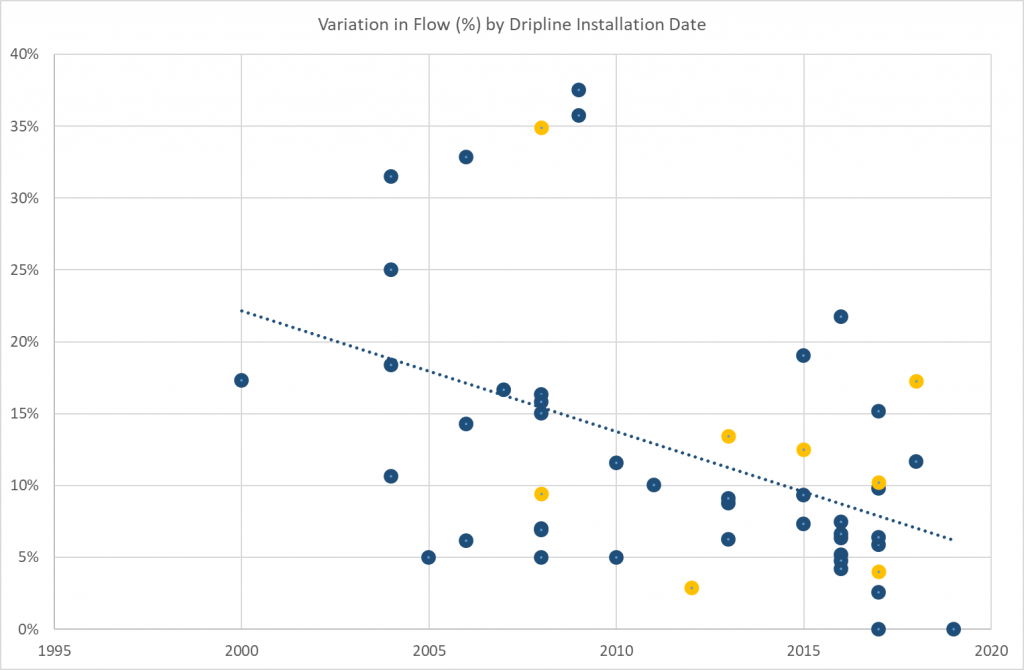

The industry audit identified a large range in performance of drip irrigation systems across the Almond industry. Ideally flow variation within a valve unit should be less than ±5%, but the audit found many sites with well in excess of this level of variation.

One of the reasons for the industry audit was to identify issues and assist the industry to address them to improve their overall water efficiency.

In this context a key finding was a loose correlation between dripline age and performance, with performance tending to deteriorate with increasing system age (Figure 2).

However, some older systems still performed within the standard, indicating that system maintenance is also critical to system performance.

Further information about the audit is available here.

The drip irrigation evaluation tool* allows irrigators to compare the results of their own drip irrigation system assessments against the 50 sites evaluated in the performance audit.

There are also links to resources to assist irrigators to identify the specific issues which might be affecting their systems, and find ways to address these issues.

Download and print data collection sheet and enter the results of your system test in to to the tool to evaluate your system performance.

*Drip evaluation tool and results summary are not supported in Internet Explorer