Energy assessments of irrigation systems across the Murray Darling Basin have highlighted huge opportunities to improve irrigation energy efficiency. However, many farms still ask:

- How can I tell if my irrigation system is energy efficient?

- What are the likely costs and benefits of improving the energy efficiency of my system?

- What parts of my system can be improved to operate more efficiently?

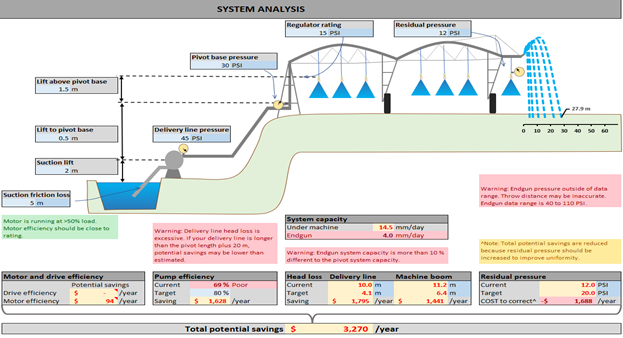

Agriculture Victoria and NSW DPI have developed a tool to help irrigators measure and benchmark the energy efficiency of their centre pivot and travelling irrigation systems. The tool allows farmers to estimate what cost savings may be possible and what parts of the irrigation system need attention. Crucially, the tool also indicates when irrigation pressure is too low, which often impacts on irrigation uniformity. Low pressure must be addressed first, and could actually result in higher pumping costs, but will result in more uniform productivity. Any increase in pumping costs will be offset by production gains.

The tool can work with both electric and diesel powered irrigation systems. It is designed to require minimal data inputs and is easy to use with the graphical display. Data you will need:

- Water use (monthly, quarterly or annual)

- Diesel or electricity usage (monthly, quarterly or annual)

- Diesel or electricity costs (monthly, quarterly or annual)

- Pump flow rates

- Pressure at specific locations on the irrigation system

- Vertical lift heights for water

- Basic system specifications (e.g. system length, regulator rating, gun type and nozzle size)

- Motor size and drive type

The tool will give an indication of how efficiently your pump is operating. The minimum acceptable pump efficiency is 70%. It will also indicate if the system pressure is within the desired operating range. Operating pressure may be too high, unnecessarily increasing costs and possibly upsetting the emitter pattern. Operating pressure also may be too low, which reduces operating costs but always diminishes irrigation performance and reduces crop productivity.

The tool calculates the pumping cost per ML and indicates both where the costs occur in your system, as well as identifying components for upgrade consideration.

Causes of excess energy use

Excess energy use can be caused by poor system design, typically in pipes being too small to carry the volume of water required at the necessary flow rate and pressure for the system to operate as intended, or incorrect pump selection. Operating outside of the pump’s optimal performance range through varied speed or incorrect impeller size reduces efficiency and increases costs. Running your system at a higher pressure than required reduces efficiency, although this determination should be based on the pressure at the furthest point of the system to ensure the emitter(s) are performing as required.

Two energy tools are currently available:

- Energy tool – centre pivot irrigation systems and

- Energy tool – travelling irrigation systems.

Both are Microsoft Excel spreadsheets and can be downloaded here:

Travelling Irrigator Energy Tool v13.2

Pivot Irrigator Energy Tool_V14.2

The tools have been developed for Microsoft Excel 365 and above. The tool has not been tested on older versions of excel.