Irrigation systems, in particular drip irrigation, will only operate properly if well maintained. By regularly monitoring and maintaining its components we can reduce blockages, deterioration of drippers, pressure irregularities, and impacts on tree health and yields.

Here we highlight some management techniques that will help irrigators to retain maximum benefits from their drip irrigation systems.

System flushing

Depending on water quality, it is recommended to give the piped system a complete flush before the first irrigation of the season, several times during the season and again at the end of the season. As a guide, flush three times a season when irrigating with clean water and at least once every fourth irrigation with dirty water.

When performing this procedure your components should be flushed in the order of water flow – mains, submains and laterals.

Quick tips:

- Only a few laterals should be opened and flushed together to ensure sufficient water flows through the line. If the laterals are connected to a flushing manifold, open one at a time only.

Disinfestation

Emitters are generally blocked due to organic and mineral sedimentation, which should be dealt with separately. Organic matter e.g., algae and biofilm are commonly treated with an oxidizing agent and mineral deposits are treated with acid. When selecting a chemical product to use, read the label thoroughly prior to use. Many of these chemical products are not registered for the specific purpose of cleaning irrigation systems. For more information about chemical usage please visit the Agriculture Victoria website and search for off-label chemical use.

Monitoring system performance

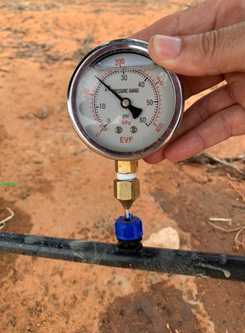

Regular monitoring of a drip irrigation system is important to make sure it’s working properly. This generally involves checking dripper discharge and operating pressure. Ideally this should occur as soon as the system is commissioned, and regularly over the life of the system.

Quick tips:

- For non-pressure compensated drippers (non-PC), the discharge stated by the manufacturer is a nominal discharge figure at a specific pressure (generally 100 kPa).

- In a properly designed system, there will be less than 10% variation in dripper discharge throughout a valve unit (i.e. less than ±5% variation).

Figure 1. a) Measure dripper discharge rates and variantion by placing containers under drippers and measuring their volumes after 36 seconds; b) Check drip line pressure using a pressure gauge with a needle attachment and a take-off point – photos: Jeremy Giddings.

For further information on filtration for drip irrigation systems visit Agriculture Victoria or Ask an expert.

This publication is provided solely for information purposes and no representation or warranty is made as to its quality, accuracy, completeness, suitability, or fitness for any particular purpose. You should make your own enquiries as to its appropriateness and suitability for your particular circumstances. The State of Victoria as represented by its Department Energy, Environment and Climate Change accepts no duty of care and disclaims all liability in relation to use of this publication.