There are two basic injection methods used to apply fertigation in drip irrigation systems: pressure differential and injection pumps.

Many factors will influence which system suits your needs best and can be dependent on your management style, skill level, farm size, layout, costs, power supply, or crop sensitivity. In this article we will dive into their differences, advantages and disadvantages, and other system components.

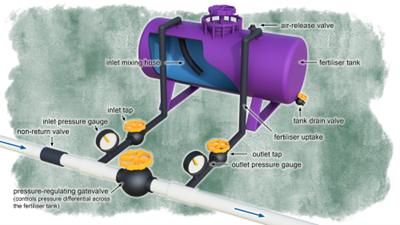

Pressure differential injection

This system works based on a pressure differential created by a valve, pressure regulation, elbows or pipe friction in the mainline, forcing water through a bypass pipe into a pressure tank and out again, carrying a varying amount of dissolved fertiliser. Two common methods are pressure tanks and venturi systems.

Pressure tank

Figure 1. Schematic diagram of pressure tank system.

Advantages

Simple and inexpensive to install and operate

Easy to maintain

Easy to alter the type of fertiliser to be injected

Power source not required.

Disadvantages

The concentration of fertiliser solution decreases over the injection period, leading to poor nutrient placement

Requires a loss in pressure in irrigation mainline/ submain

Proportional fertigation is not practical on large scale systems

Unsuitable for automation

Tank and piping must be sealed and able to withstand mainline pressure

Liquids are preferred and give best results due to a lack of agitation for powder formulations

Tank size limits this method to relatively small irrigation systems.

Venturi system

Advantage

Simple to install, operate and maintain

Suitable for proportional fertigation

Injection rate adjustable

Injection rates can be controlled with a metering valve.

Disadvantage

Requires pressure loss in mainline (can be 30%) or a booster pump

Unsuitable for larger properties

Quantitative fertigation is difficult for basic systems. Advanced venturi systems allow larger flow rates and proportional injection.

Injection Pumps

Injection energy can be provided by electric motors, impeller-driven power units and water-driven hydraulic motors

Electric injection pumps

Advantages

Simple to install, operate and maintain

Suitable for either proportional or quantitative fertigation

Injection rate is adjustable

No pressure loss in mainline

Suitable for automation.

Electric power source required

Pump must develop minimum mainline pressure to operate.

Disadvantages

Electric power source required

Pump must develop minimum mainline pressure to operate.

Hydraulic injection pumps

Advantage

Electric power source not required

Portable

Simple to install, operate and maintain

Suitable for either proportional or quantitative fertigation

Injection rate is adjustable

Units utilising mainline pressure do not induce mainline pressure loss

Highly suitable for automation, low labour requirement.

Disadvantage

Regular maintenance required

Pumps require a minimum line pressure

Suitable for smaller systems only

Can create wastewater which requires disposal.

Figure 2. Portable hydraulic injection pump – photo: Peter Henry

Monitoring Ph and EC

To optimise fertiliser uptake and reduce the likelihood of chemical precipitation, some irrigators choose to maintain the pH of the solution (usually pH 5.5 – 7 depending on the crop and situation). Probes are also available for monitoring EC, which can be helpful when intensively fertigating sensitive crops or at sensitive growth stages. Some managers practicing intensive fertigation may also be interested in monitoring electrical conductivity (EC) to avoid injecting a solution greater than the upper salinity limit that can be tolerated by the crop being fertigated.

Figure 3. pH and EC probe – photo: Peter Henry

To dive deeper into Fertigation tips visit Agriculture Victoria or Ask an expert.

This publication is provided solely for information purposes and no representation or warranty is made as to its quality, accuracy, completeness, suitability, or fitness for any particular purpose. You should make your own enquiries as to its appropriateness and suitability for your particular circumstances. The State of Victoria as represented by its Department Energy, Environment and Climate Change accepts no duty of care and disclaims all liability in relation to use of this publication.