The NSW DPI Energy Efficiency Solutions project has implemented pilot projects on a range of farms around NSW during 2021 to address the cost, reliability and the sustainability of energy use on farms. One of these pilots was implemented at Pecora Dairy, a sheep dairy and boutique cheese producer in Robertson, NSW, owned by Michael and Cressida Cains. The business is committed to producing environmentally friendly and unique food products and in April 2019 Pecora Dairy was awarded the first raw cheese processor license from NSW Food Authority.

Michael and Cressida at the sheep dairy

The pilot at Pecora Dairy entailed the installation of 28 kW of solar photovoltaics, a 40-kWh flow battery system and a new heat pump to replace the site’s LPG boiler. This solution has overcome the energy supply issues, power outages and an insecure supply of LPG that plagued the dairy and threatened processing operations.

Pecora Dairy machinery shed batteries and electronics

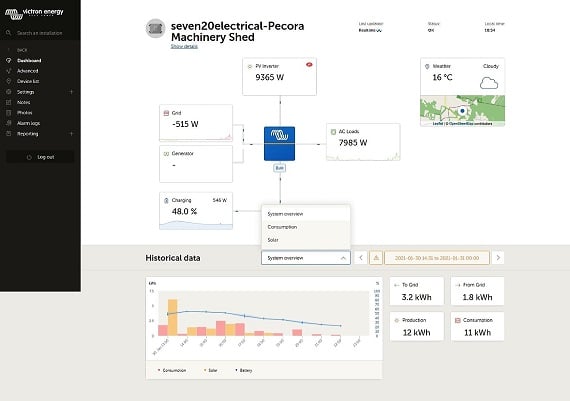

Pecora Dairy’s solar and battery storage system will be combined with a peer-to-peer (P2P) energy trading platform to sell and purchase excess solar electricity with other P2P users on the platform. This system supports the grid in powering the farm’s operation and has remote monitoring so you can see where the power is coming from and moving to. The screen shot below shows solar providing all the dairy’s power, recharging the battery and exporting 515 Watts of electricity into the grid. This changes constantly depending on the level of solar generation, with the battery charging or discharging to help balance the load.

Michael and Cressida are very enthusiastic about renewables and long-term sustainability. The project means they are now unaffected by blackouts which previously caused loss of valuable cheese stock and productivity. It also has reduced their reliance on fossil fuels, reduced costs and added to the business’s branding appeal. Michael notes, “We are Australia’s first registered uncooked, raw cheese producer, so product quality and safety are vital. The updated power system safeguards our production and lets us sleep well on stormy nights!”.

For more information about renewable energy options in dairy systems, see:

Meredith Dairy – Innovations in Renewable Energy

Energy Efficiency on Dairy Farms – Webinar recording

2 comments, add yours.

William Goode

Rather than 515w maybe the peak ?

Energy Smart Farming

HI William

Thanks for the comment. Yes the 515 Watts feed in is not the peak. The system manages battery charge and grid input/export levels and is constantly changing depending on load and solar levels.

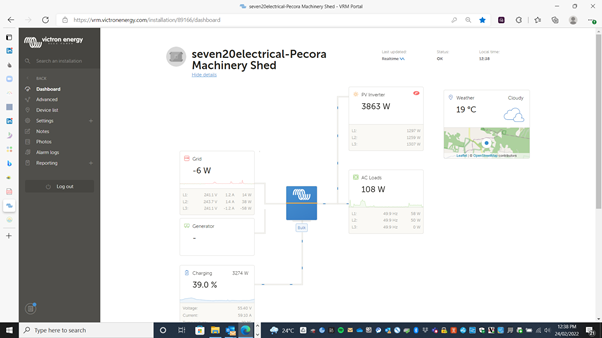

I took a screen shot of the management program to show that live information from the site was available to the managers. This was from the smaller system they have ( the 28 kW system is set up over 2 sheds and they operate independently).

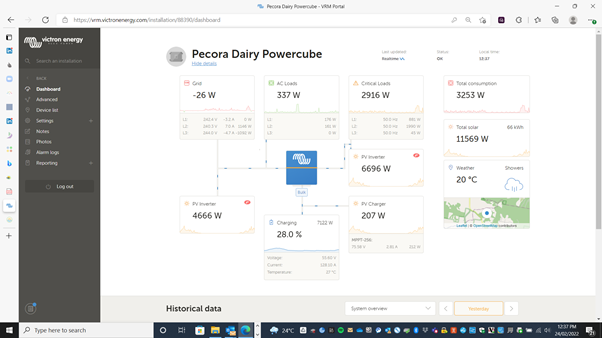

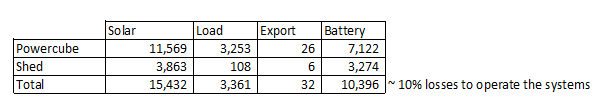

This is the other larger system this morning and the smaller one is below.

So at the time of the screenshot:

The batteries are absorbing the majority of the power for later use, with minimal exports as this is their lowest-cost power. When the batteries are full the export level will increase.

Hope that helps

Cheers, John O’Connor (JOC)